Product advantages

- outstanding resistance of temperature and corrosion

- high durability

- excellent acoustic absorption

- perfect volume retention by optimal nozzle level

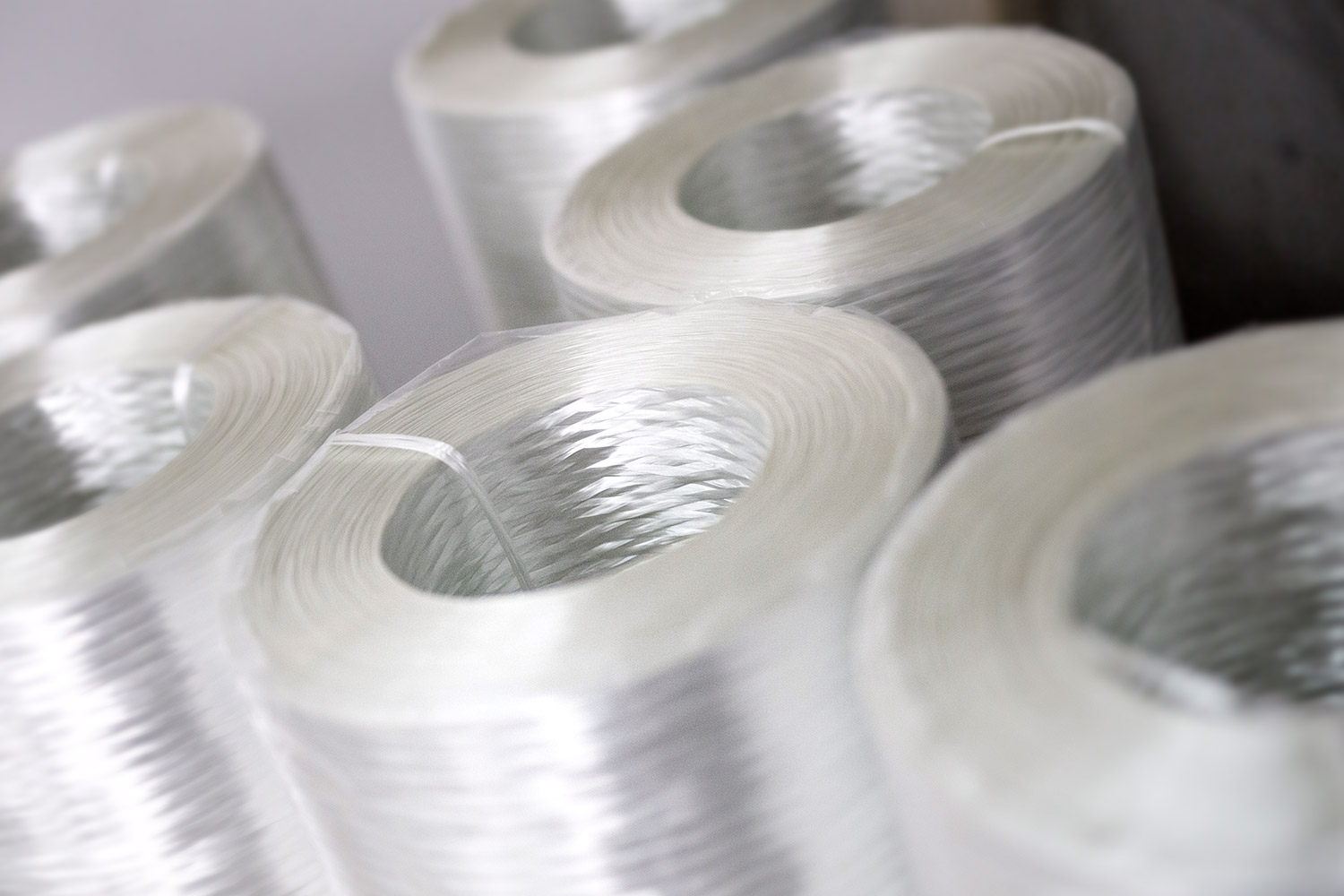

For extrem temperature exhaust systems and silencer direct filling: powertex®. The excellent sound absorbency of this textile glass fiber sets a new standard and represents a significant contribution to the techniques of noise reduction in modern vehicles. Environmentally friendly, the new glass formulation of powertex® continuous filament also offers high corrosion resistance and thermal durability.

Heat and vibration are no problem for powertex®. As there is zero blow-out, even under the harshest conditions, the volume of the continuous filament is maintained for long periods. The result: excellent acoustic absorption and thermal insulation over the entire life of the muffler.

The high chemical resistance of powertex® is documented in corrosion tests with acid and alkali solutions. These standard test methods display the resistance to the type of substances that condense from exhaust gases within the muffler. powertex® fiber achieves the best marks for corrosion resistance.

Tensile strength at high temperature

The diagram compares the heat resistance of powertex®, a comparable 24 µm continuous glass fiber and E glass fibers. The tensile strength of the individual glass filaments was measured after exposure to increasing temperatures. powertex® demonstrates superior performance when exposed to heat. This guarantees a high level of mechanical stability and hence a long service life for the fibers in the muffler.

Supply and process support

DBW Advanced Fiber Technologies offers comprehensive associated services with powertex®. The customer's requirements and circumstances are established and recorded in the course of thorough consultations. Following the construction of prototypes, services provided include prefabrication to the customer's specifications and delivery of powertex® in the volumes and at the times required. There are also thorough advisory services on the processing of powertex® and, as required, the acquisition and installation of processing equipment, in particular the equipment for the direct filling of roving filaments. Of course, ongoing, on-site consultation during start-up, as well as production support are included in our service package.