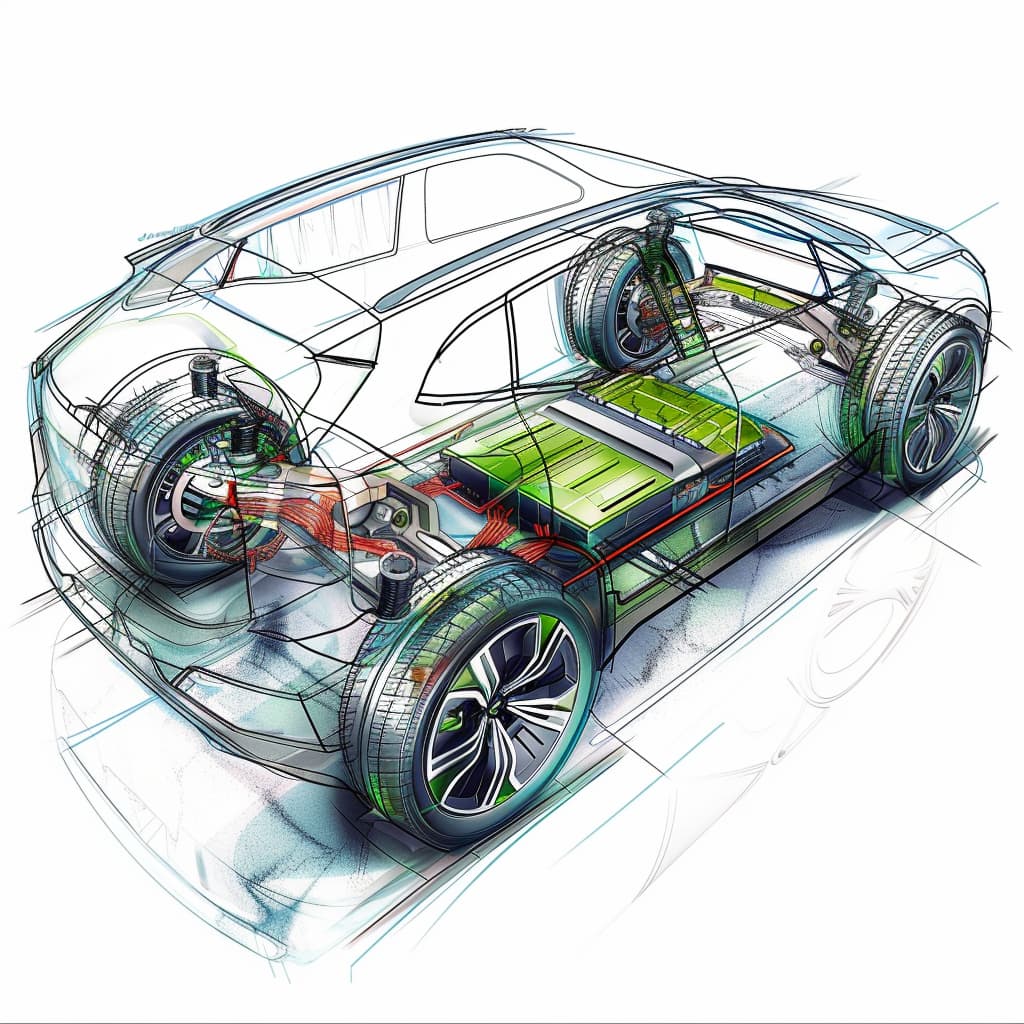

The steadily increasing demand for electric vehicles and plug-in hybrids shows that they are gaining ever greater importance as an environmentally friendly alternative to conventional combustion engines. At the same time, alternative drive concepts bring new thermal and acoustic requirements, for which we offer innovative, customized solutions. Our products make a decisive contribution to significantly enhancing safety and driving comfort.

Our materials offer you clear benefits that are indispensable for modern vehicle construction:

Customized material compositions for specific challenges

Recyclable materials for greater sustainability

Integrated process chain from development to prototyping and series production

Optimized thermal and acoustic properties for maximum comfort and safety

In electric vehicles, high‑voltage battery thermal management is a core challenge because performance and ageing are highly temperature‑dependent. Lithium‑ion batteries operate reliably within a moderate temperature window; many references cite ranges around 15–35 °C, with practical “ideal” operating windows often described near 20–40 °C depending on chemistry and use case. Effective thermal insulation cuts heat losses in cold conditions and heat ingress in hot environments, lowering active heating/cooling demand and supporting range, efficiency, and cell lifetime. In addition, a propagation protection approach limits thermal runaway spread across cells or modules; a dedicated Propagation Protection System can buy valuable time for passenger evacuation during an event and help maintain pack integrity for longer.

Although modern electric vehicles and e-cars are significantly quieter than vehicles with combustion engines, there are still various sources of noise that require professional acoustic insulation and soundproofing. The primary sources of noise include wind and tire rolling noise, high-frequency sounds from electrical components such as electric motors (500-10,000 Hz), inverters (5-15 kHz), and transmissions, as well as noise from air conditioning and cooling systems. Effective acoustic insulation with modern insulation materials such as expanded polypropylene (EPP), polyurethane foams, or mineral wool contributes significantly to increased driving comfort and reduces noise pollution in the interior. Professional NVH (noise, vibration, harshness) solutions for electric mobility include special motor covers, sound insulation for wheel arches, and other acoustic coverings that effectively absorb disturbing vibrations and noises. EVs are up to 20 dB quieter than combustion engines at low speeds (0-20 km/h), but the values even out to less than 5 dB at higher speeds. Optimal noise insulation significantly improves driving comfort.

In addition to manufacturing and processing highly effective acoustic and thermal materials, we are the only manufacturer worldwide that can also handle the development, prototyping, and series production of components. Upon request, our customers receive everything from a single source, from the initial problem to the finished component. The advantages of our materials and products at a glance:

There are a variety of materials and solutions that can be used for thermal and acoustic insulation in electric vehicles. These include:

The selection of the right materials and solutions depends on various factors, such as the specific requirements of the vehicle, costs, and environmental compatibility. By using advanced thermal and acoustic insulation based on our biosil® material, electric vehicles can be made not only more comfortable and quieter, but also more efficient and environmentally friendly. This helps to increase the acceptance and spread of alternative drive concepts.